Dec 2, 2025

Read More

Transforming Critical Materials Production with Clean, Microbial Innovation for a Secure Energy Future.

Transforming Critical Materials Production with Clean, Microbial Innovation for a Secure Energy Future.

Transforming Critical Materials Production with Clean, Microbial Innovation for a Secure Energy Future.

We use engineered bacteria to recover critical metals from ores and unconventional feedstocks—efficiently and economically, with no harsh chemicals or high heat.

Genetically-Optimized

Bacterial Technology

We recover rare earth elements from by-products of existing recycling industries, supporting a circular and secure supply chain with lower geopolitical risks.

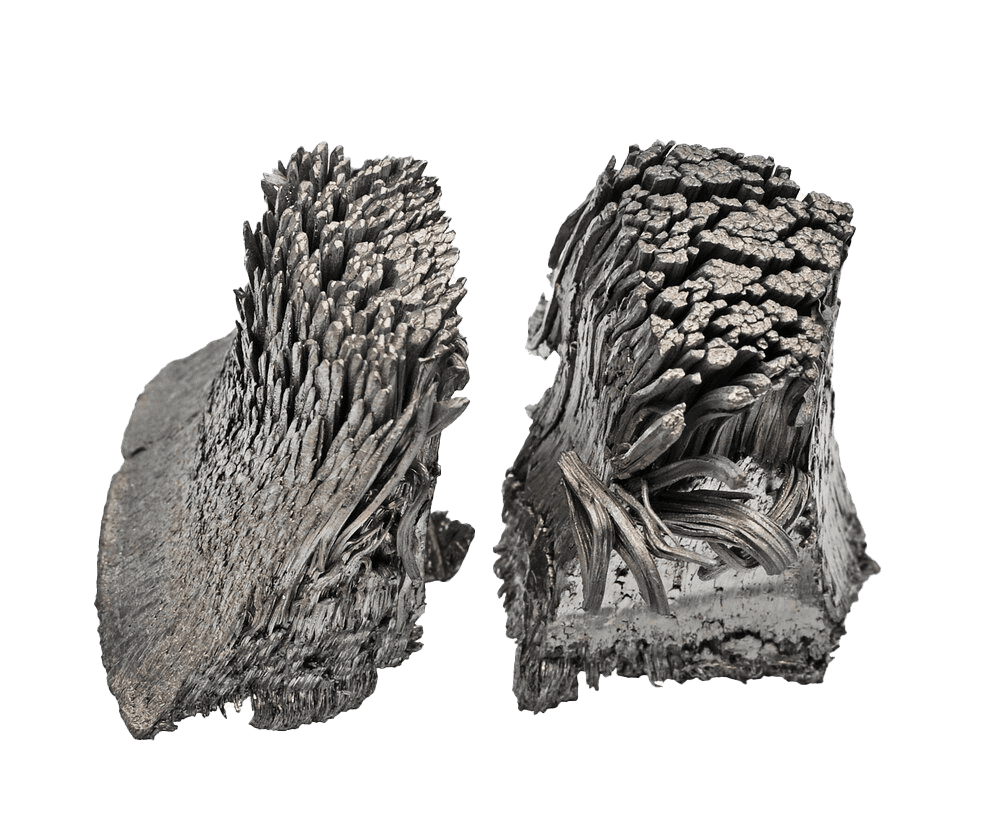

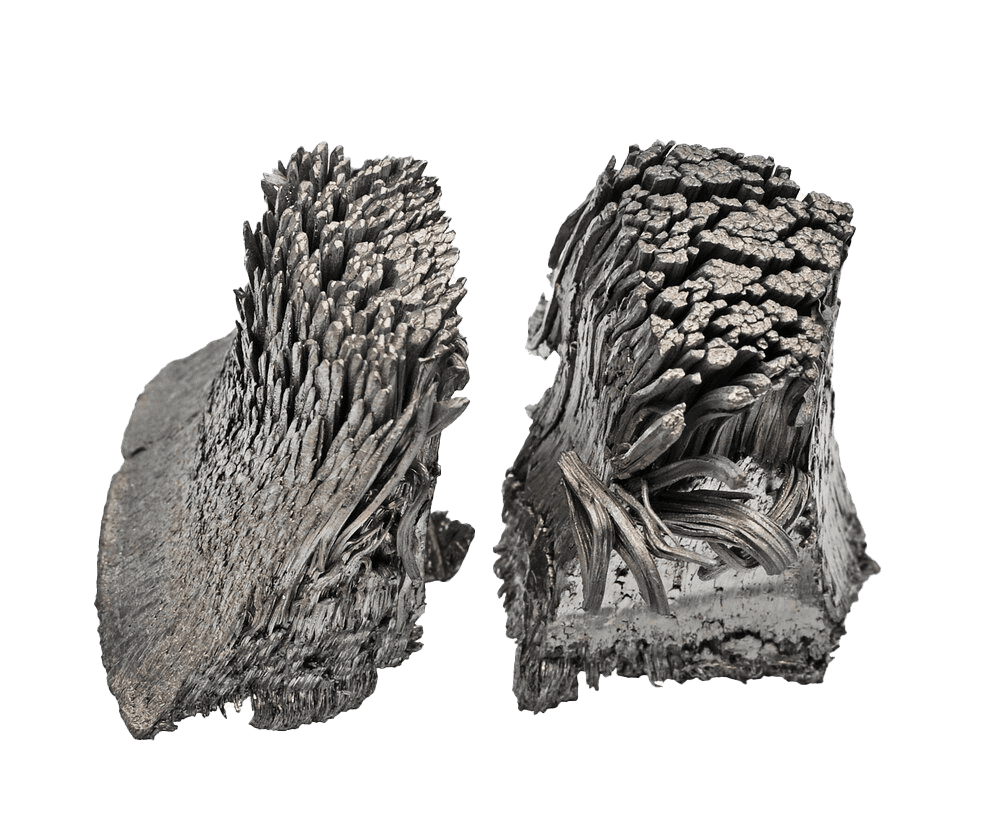

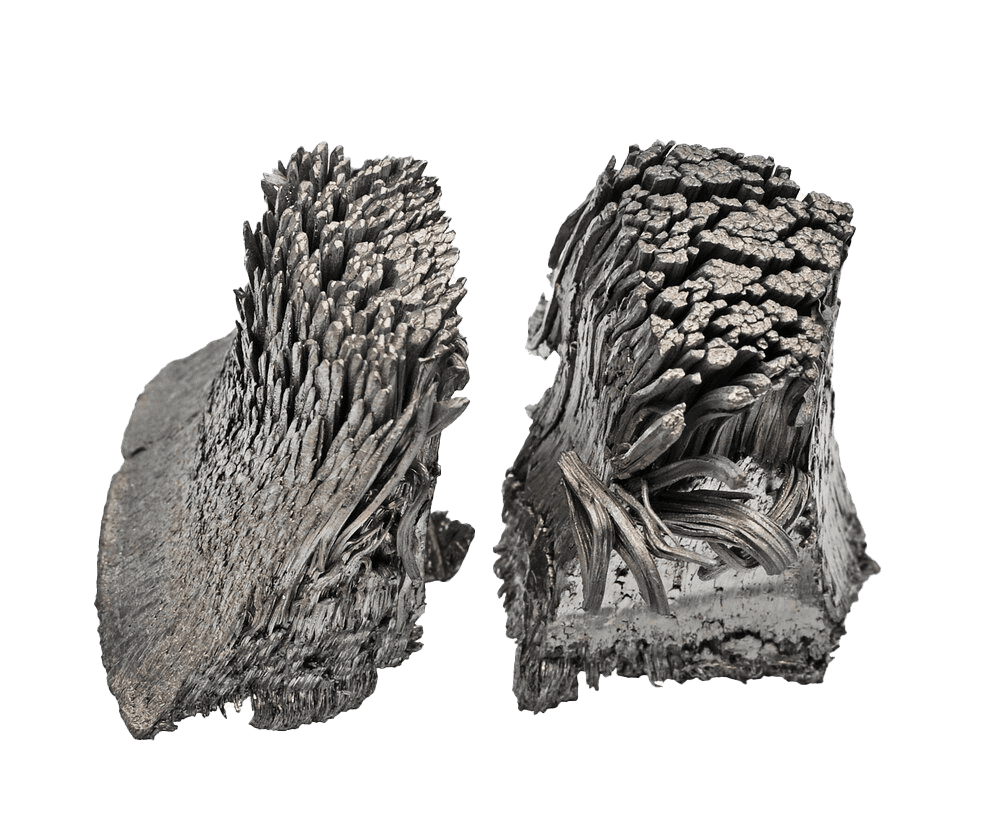

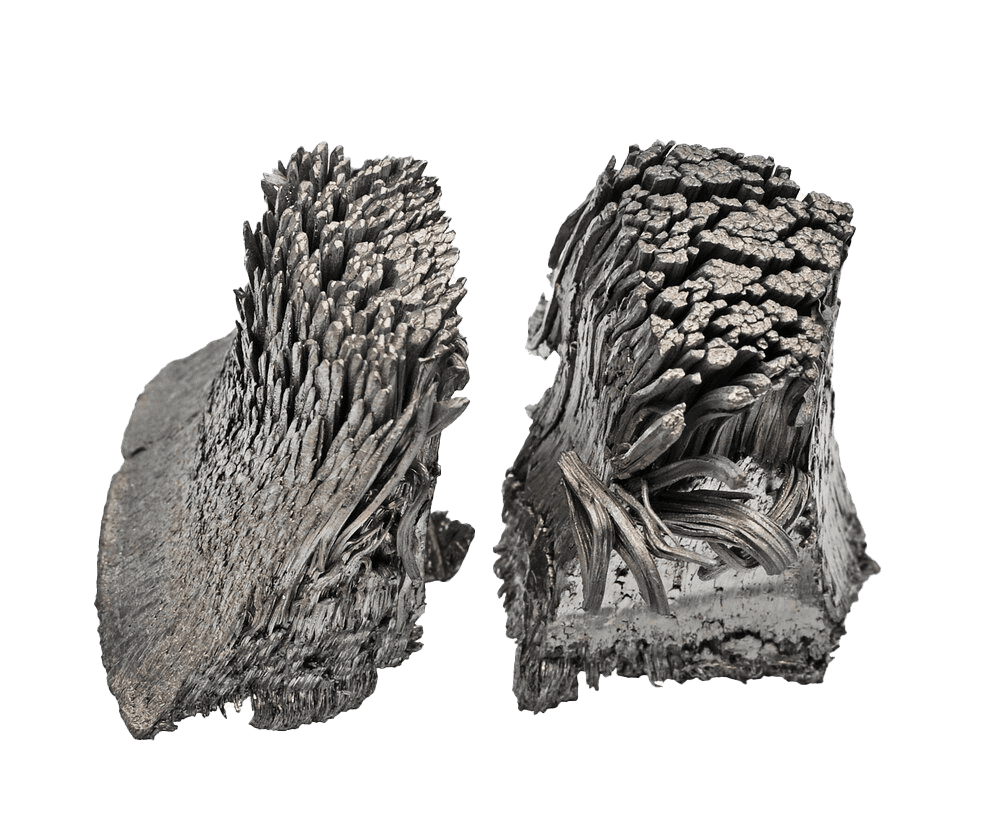

Steel Slag

Electronic Waste

Spent Catalysts

Coal Ash

REE-containing Industrial Residuals

Genetically-Optimized

Bacterial Technology

Biology at work

We use engineered bacteria to recover rare earth elements from ores and unconventional feedstocks—efficiently and economically, with no harsh chemicals or high heat.

Steel Slag

Electronic Waste

Spent Catalysts

Coal Ash

REE-containing Industrial Residuals

Turning waste into resource

We recover rare earth elements from by-products of existing recycling industries, supporting a circular and secure supply chain with lower geopolitical risks.

We use engineered bacteria to recover critical metals from ores and unconventional feedstocks—efficiently and economically, with no harsh chemicals or high heat.

Genetically-Optimized

Bacterial Technology

We recover rare earth elements from by-products of existing recycling industries, supporting a circular and secure supply chain with lower geopolitical risks.

Steel Slag

Electronic Waste

Spent Catalysts

Coal Ash

REE-containing Industrial Residuals

Genetically-Optimized

Bacterial Technology

Biology at work

We use engineered bacteria to recover rare earth elements from ores and unconventional feedstocks—efficiently and economically, with no harsh chemicals or high heat.

Steel Slag

Electronic Waste

Spent Catalysts

Coal Ash

REE-containing Industrial Residuals

Turning waste into resource

We recover rare earth elements from by-products of existing recycling industries, supporting a circular and secure supply chain with lower geopolitical risks.

Our optimized bioleaching bacteria produce organic, biodegradable acids to extract metals safely and efficiently, reducing environmental harm compared to conventional methods.

Sustainable REEs

Sustainable REEs

Cleaner methods

Our optimized bioleaching bacteria produce organic, biodegradable acids to extract metals safely and efficiently, reducing environmental harm compared to conventional methods.

Our optimized bioleaching bacteria produce organic, biodegradable acids to extract metals safely and efficiently, reducing environmental harm compared to conventional methods.

Sustainable REEs

Sustainable REEs

Cleaner methods

Our optimized bioleaching bacteria produce organic, biodegradable acids to extract metals safely and efficiently, reducing environmental harm compared to conventional methods.

Clean, Efficient, and Biological Solutions

Genetically-Optimized

Bacterial Technology

Biology at work

We use engineered bacteria to recover rare earth elements from ores and unconventional feedstocks—efficiently and economically, with no harsh chemicals or high heat.

Genetically-Optimized

Bacterial Technology

Biology at work

We use engineered bacteria to recover rare earth elements from ores and unconventional feedstocks—efficiently and economically, with no harsh chemicals or high heat.

Steel Slag

Electronic Waste

Spent Catalysts

Coal Ash

REE-containing Industrial Residuals

Turning waste into resource

We recover rare earth elements from by-products of existing recycling industries, supporting a circular and secure supply chain with lower geopolitical risks.

Steel Slag

Electronic Waste

Spent Catalysts

Coal Ash

REE-containing Industrial Residuals

Turning waste into resource

We recover rare earth elements from by-products of existing recycling industries, supporting a circular and secure supply chain with lower geopolitical risks.

Sustainable REEs

Cleaner methods

Our optimized bioleaching bacteria produce organic, biodegradable acids to extract metals safely and efficiently, reducing environmental harm compared to conventional methods.

Sustainable REEs

Cleaner methods

Our optimized bioleaching bacteria produce organic, biodegradable acids to extract metals safely and efficiently, reducing environmental harm compared to conventional methods.

Clean, Efficient, and Biological Solutions

Current methods of rare earth extraction are harmful, expensive, and inefficient. They pose significant environmental risks.

Current methods of rare earth extraction are harmful, expensive, and inefficient. They pose significant environmental risks.

Production methods generate massive amounts of acidic and radioactive waste.

Production methods generate massive amounts of acidic and radioactive waste.

Current supply chains can’t keep up with the 12% annual growth in demand for rare earth elements.

Current supply chains can’t keep up with the 12% annual growth in demand for rare earth elements.

Manufacturing a single wind turbine requires 2 tons of rare earth elements.

Manufacturing a single wind turbine requires 2 tons of rare earth elements.

With 58% of mining, 89% of separation, and 90% of refining happening in China, our supply chain is vulnerable and risky.

With 58% of mining, 89% of separation, and 90% of refining happening in China, our supply chain is vulnerable and risky.

Production methods generate massive amounts of acidic and radioactive waste.

Current supply chains can’t keep up with the 12% annual growth in demand for rare earth elements.

Manufacturing a single wind turbine requires 2 tons of rare earth elements.

With 58% of mining, 89% of separation, and 90% of refining happening in China, our supply chain is vulnerable and risky.

Production methods generate massive amounts of acidic and radioactive waste.

Current supply chains can’t keep up with the 12% annual growth in demand for rare earth elements.

Manufacturing a single wind turbine requires 2 tons of rare earth elements.

With 58% of mining, 89% of separation, and 90% of refining happening in China, our supply chain is vulnerable and risky.

Driven by Purpose, Powered by Innovation

We reduce environmental and security risks of conventional mining. We're committed to smarter methods for securing critical elements.

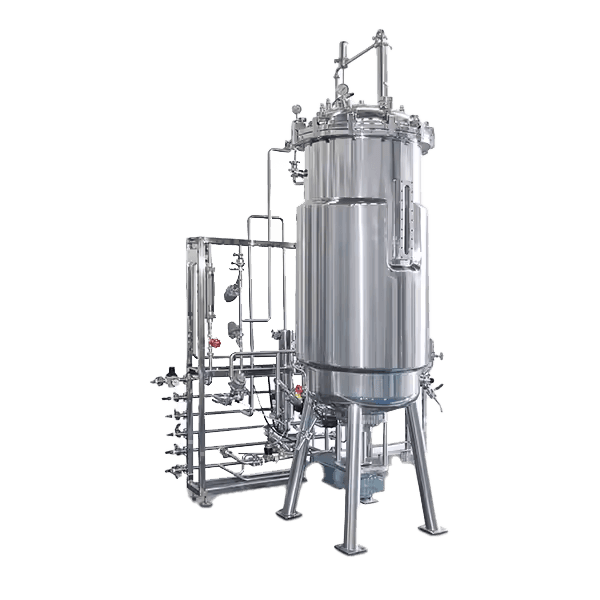

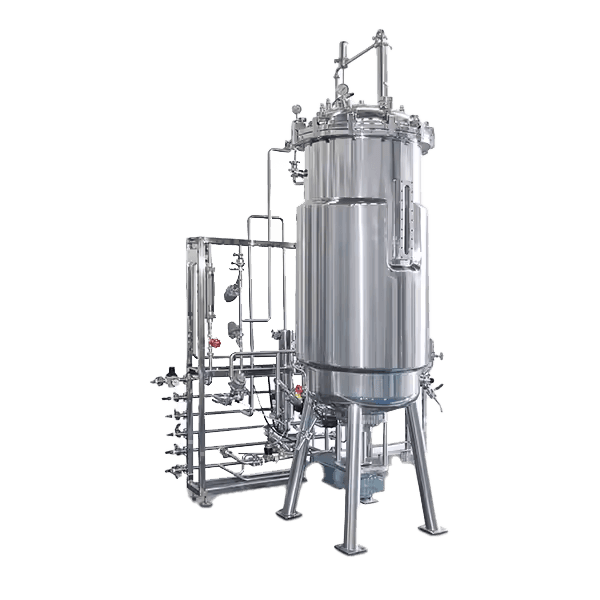

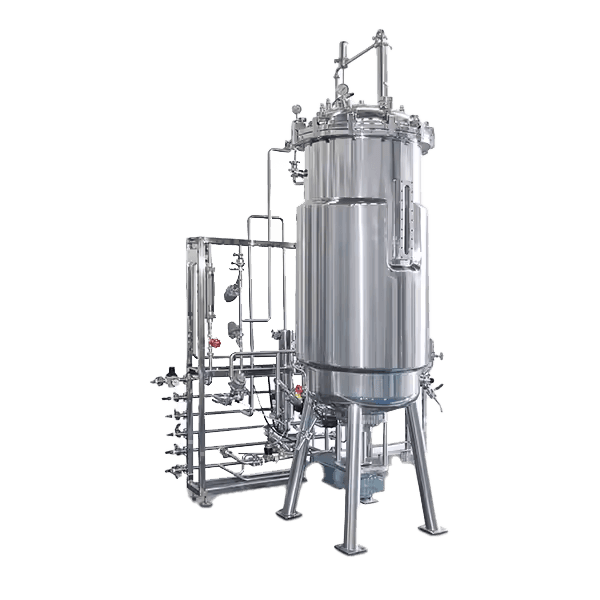

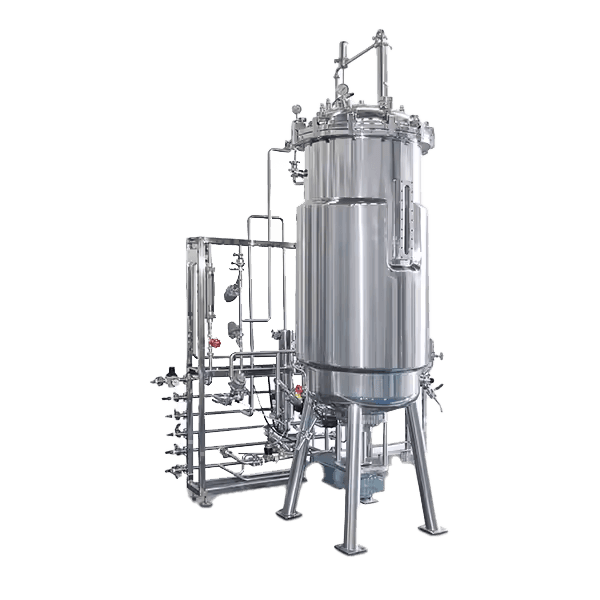

Optimized Microbial Extraction

We engineer microbes to optimize metal recovery at low temperature and pressure, and with minimal environmental impact.

Tailored Microbial Separations

High-throughput genetic engineering strategies allow us to rapidly tailor our bacteria to accommodate a wide variety of critical metal feedstocks.

Driven by Purpose, Powered by Innovation

We reduce environmental and security risks of conventional extraction. We're committed to smarter methods for securing rare earth metals .

Optimized Microbial Extraction

To efficiently extract rare earth metals with low temperature, low pressure, and minimal environmental impact, we use specially engineered bacteria.

Tailored Microbial Separations

High-throughput genetic engineering strategies allow us to rapidly tailor our bacteria to accommodate a wide variety of rare earth feedstocks.

Driven by Purpose, Powered by Innovation

We reduce environmental and security risks of conventional extraction. We're committed to smarter methods for securing rare earth metals .

Optimized Microbial Extraction

To efficiently extract rare earth metals with low temperature, low pressure, and minimal environmental impact, we use specially engineered bacteria.

Tailored Microbial Separations

High-throughput genetic engineering strategies allow us to rapidly tailor our bacteria to accommodate a wide variety of rare earth feedstocks.

Driven by Purpose, Powered by Innovation

We reduce environmental and security risks of conventional extraction. We're committed to smarter methods for securing rare earth metals .

Optimized Microbial Extraction

To efficiently extract rare earth metals with low temperature, low pressure, and minimal environmental impact, we use specially engineered bacteria.

Tailored Microbial Separations

High-throughput genetic engineering strategies allow us to rapidly tailor our bacteria to accommodate a wide variety of rare earth feedstocks.

Driven by Purpose, Powered by Innovation

We reduce environmental and security risks of conventional extraction. We're committed to smarter methods for securing rare earth metals .

Optimized Microbial Extraction

To efficiently extract rare earth metals with low temperature, low pressure, and minimal environmental impact, we use specially engineered bacteria.

Tailored Microbial Separations

High-throughput genetic engineering strategies allow us to rapidly tailor our bacteria to accommodate a wide variety of rare earth feedstocks.

Mission

Vision

Mission

Vision

Mission

Vision

Mission

Vision

Mission

Vision

Mission

Vision

Mission

Vision

Mission

Vision

Mission

Vision

Mission

Vision

Mission

Vision

Mission

Vision

SCROLL

As China dominates key stages in rare earth production, REEgen is stepping in with innovative biorecovery processes to create a cleaner, circular, and more diversified supply chain.

As China dominates key stages in rare earth production, REEgen is stepping in with innovative biorecovery processes to create a cleaner, circular, and more diversified supply chain.

Country Distribution

China | 60%

Others | 40%

Separation

Country Distribution

China | 90%

Others | 10%

Reduction

Country Distribution

China | 90%

Others | 10%

End Use

Country Distribution

China | 40%

Others | 60%

Country Distribution

China | 60%

Others | 40%

Separation

Country Distribution

China | 90%

Others | 10%

Reduction

Country Distribution

China | 90%

Others | 10%

End Use

Country Distribution

China | 40%

Others | 60%

Country Distribution

China | 60%

Others | 40%

Separation

Country Distribution

China | 90%

Others | 10%

Reduction

Country Distribution

China | 90%

Others | 10%

End Use

Country Distribution

China | 40%

Others | 60%

Stay updated on our breakthroughs, milestones, and industry insights

Stay updated on our breakthroughs, milestones, and industry insights

Dec 2, 2025

Read More

Dec 2, 2025

Read More

Oct 31, 2025

Read More

Sep 17, 2025

Read More

Aug 8, 2025

Read More

May 5, 2025

Read More

Feb 6, 2025

Read More

Mar 27, 2024

Read More

Nov 20, 2023

Read More

Sep 13, 2023

Read More

Oct 6, 2022

Read More

Dec 2, 2025

Read More

Dec 2, 2025

Read More

Oct 31, 2025

Read More

Sep 17, 2025

Read More

Aug 8, 2025

Read More

May 5, 2025

Read More

Feb 6, 2025

Read More

Mar 27, 2024

Read More

Nov 20, 2023

Read More

Sep 13, 2023

Read More

Oct 6, 2022

Read More

Dec 2, 2025

Read More

Dec 2, 2025

Read More

Oct 31, 2025

Read More

Sep 17, 2025

Read More

Aug 8, 2025

Read More

May 5, 2025

Read More

Feb 6, 2025

Read More

Mar 27, 2024

Read More

Nov 20, 2023

Read More

Sep 13, 2023

Read More

Oct 6, 2022

Read More

Be part of a team that's shaping the future of sustainable critical mineral production.

Available Positions

Be part of a team that's shaping the future of sustainable critical mineral production.

Available Positions

Be part of a team that's shaping the future of sustainable critical mineral production.

Available Positions

Learn more about our cutting-edge solutions in rare earth extraction and explore industry partnerships. We're here to connect—reach out and let's drive innovation together.

Learn more about our cutting-edge solutions in rare earth extraction and explore industry partnerships. We're here to connect—reach out and let's drive innovation together.

Learn more about our cutting-edge solutions in rare earth extraction and explore industry partnerships. We're here to connect—reach out and let's drive innovation together.